Contact Us

Roller Conveyor Shot Blast Machine

- Commodity name: Roller Conveyor Shot Blast Machine

- Product Description

-

Product Description

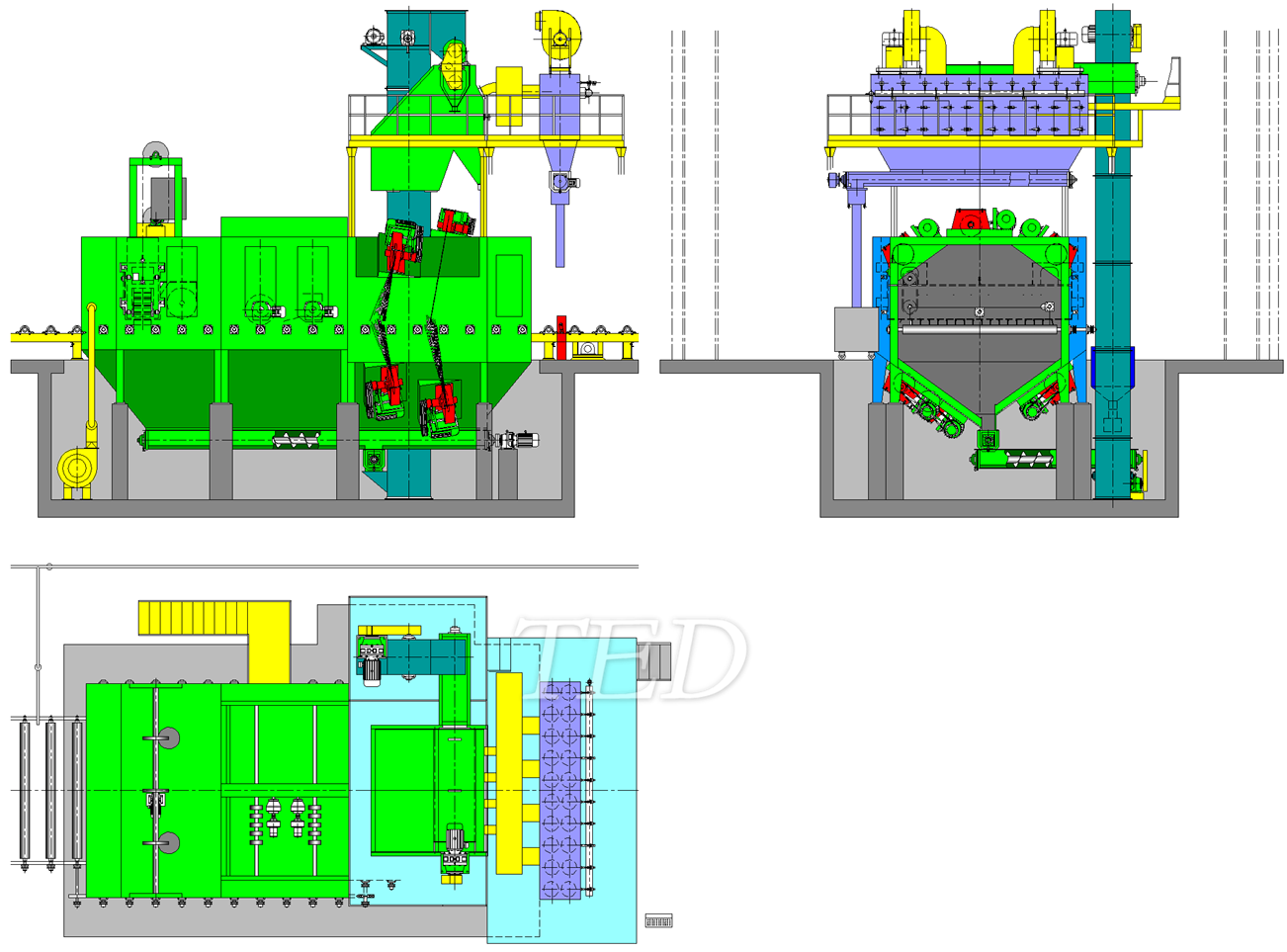

The use of roller blasting machines (continuous tunnel devices) can effectively clean the surfaces of metal plates, profiles and composite structures.

The "TS-RP" type shot blasting adopts a horizontal roller conveyor different from the "TS-RLV" type and is compatible with the vertical roller conveyor.

The "TS-BM" series of tapered roller peening machines are specially designed for handling multiple bars, round bars, hexagonal bars or steel at one time.

For these types of shot blasting machines, the parts to be processed are placed on the entrance roller conveyor by a bridge crane or forklift (not included in our scope of supply). The motorized roller conveyor is equipped with a feed speed adjustment (inverter) to introduce the workpiece into the shot blasting chamber; a series of turbines appropriately positioned around the workpiece channel section provide the metal abrasive to be projected onto the surface to be cleaned in a single cycle.

The size of the roller conveyor will be determined according to the size of the workpiece to be processed.

The layout and number of turbines, placed above and below the rolling surface, means that all surfaces to be pickled can be completely cleaned in one cycle.

Suitable for metal plates from 500 to 3500mm, and profiles up to 600mm.

Product Video

Keywords:

Customer Case

Honors

More Products

QINGDAO TAIDE MACHINERY CO., LTD

Tel: +86-0532-86199296

E-mail: krystal@qdtedmachine.com

Address: 1089 Zhaizishan Road, Huangdao District, Qingdao, Shandong, China

Customer Message

Copyright © 2024 QINGDAO TAIDE MACHINERY CO., LTD | SEO | Business License